How a Car Engine Works

ZQvfHyfgBtA — Published on YouTube channel Animagraffs on March 13, 2021, 5:26 PM

Watch VideoSummary

This summary is generated by AI and may contain inaccuracies.

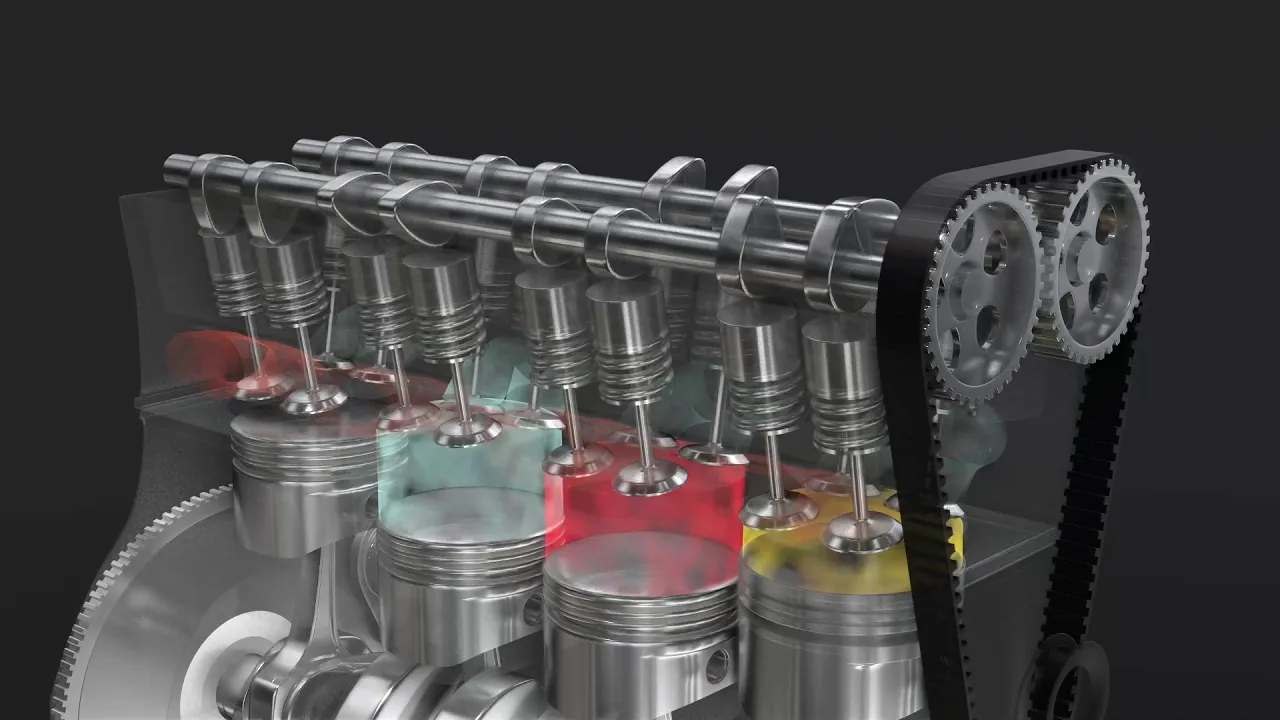

Here is a summary of the transcript about how a car engine works: The transcript explains the four stroke cycle that each piston goes through - intake, compression, power, and exhaust. It describes how the pistons connect to the crankshaft to translate power out of the engine. The firing order of the pistons is coordinated by camshafts and timing belts/chains. The transcript discusses the engine block, cylinder heads, flywheel, starter, and different cylinder configurations. It then covers the main systems that support the engine: - Air Intake - brings in air through a filter and intake manifold where it mixes with fuel before entering the cylinders. - Fuel System - fuel pump, lines, filter, and injectors deliver fuel at the right time and ratio. - Cooling System - coolant circulates through radiator and engine to keep temperatures in safe range. - Electrical System - spark plugs ignite fuel/air mix as directed by ECM; alternator generates electricity; battery provides power. - Oil System - oil lubricates and cools the engine, oil pump circulates it, filter cleans it. - Exhaust System - exhaust manifold, catalytic converter, and muffler deal with engine exhaust. The transcript provides an overview of the key components and systems that enable an internal combustion engine to generate power.

Video Description

An inside look at the basic systems that make up a standard car engine.

Alternate languages:

Español: https://www.youtube.com/watch?v=FpLfFcfgtzE

Get on Patreon and help fund my 3D animation obsession! It wouldn't feel right to put sponsorship segments in the middle of high quality educational content, so let's try another way together:

https://www.patreon.com/animagraffs

Need 3D illustration and animation? Have suggestions for what to explain next? Animagraffs can help! Let's chat: https://animagraffs.com/contact/

License Animagraffs work for your own purposes

https://animagraffs.com/licensing/

See more explanations of how things work at: https://animagraffs.com/

I use Blender 3D to create these models. It's free and open source, and the community is amazing:

https://www.blender.org/

Chapters

0:00 Intro

0:14 4 Stroke Cycle

1:22 Firing Order

1:36 Camshaft / Timing Belt

1:56 Crankshaft

2:15 Block / Heads

2:35 V6 / V8

3:02 Air Intake

3:25 Fuel

3:54 Cooling

5:02 Electrical

6:06 Oil

7:03 Exhaust

7:28 Full Model

Transcription

This video transcription is generated by AI and may contain inaccuracies.

I'm Jake O'Neill, creator of anamographs. And this is how a car engine works. Let's start at a single piston, the powerhouse of the engine, and work our way outwards. The four stroke cycle. When a piston travels to the end of its range, whether up or down, that's a stroke. Car engines use a four stroke cycle, and it goes like this. First intake. The piston descends, sucking an air fuel mixture into the cylinder through the intake port. With both intake valves open. Next, compression. With all valves closed, the piston comes back up, compressing the fuel and air mixture for more powerful combustion. Then, the power stroke. An electrical spark ignites the compressed fuel and air mixture, and the resulting combustion forces the piston to the bottom of the cylinder. Again, a connecting rod transfers this power to the crankshaft. Finally, exhaust. The piston comes back up, pushing the spent mixture out through open exhaust valves and the exhaust port, connecting multiple pistons for smooth power delivery. Pistons take turns firing. The firing order for this engine is 1342 camshafts with specially shaped cams. Push spring loaded valves open in turn cam gears and a timing belt or chain links everything to the crankshaft, and it all spins together. The crankshaft translates piston power out of the engine. It has counterweights to balance against the pistons for perfectly smooth revolutions. This is what rpm means. We're counting the number of full crankshaft revolutions per minute. The engine block holds the crankshaft and cylinders, and the cylinder head holds valves, ports, cams, etcetera. A geared flywheel sits at one side of the crankshaft for connection to a transmission. It's also where the starter connects to the system. This engine has four cylinders arranged in a single row, but there are many other possible configurations, like six cylinders, with three on each side angled in a v shape or eight. Despite different design goals, the basic engine parts are all there. Now let's look at other systems that support this combustion process. Air intake air comes in through the air filter and then into the intake manifold, where it mixes with fuel before being sucked into individual cylinders through intake ports. Fuel the fuel pump carries gas from the tank through a fuel filter to the engine, where fuel injectors emit a precisely timed spray of gas into the intake port. Cooling engines get very hot during operation and require a cooling system. Coolant channels around the cylinders and through the cylinder heads carry a special liquid called antifreeze to keep temperatures within safe operating range. It's called antifreeze because it won't freeze in icy weather after cooling hot engine parts. Coolant circulates through the radiator. The radiator has a network of small tubes and fins. Coolant passes through these channels while air pulled in by the radiator fan blows by the tubes, cooling the hot liquid for recirculation. A water pump keeps the coolant system flowing and properly pressurized. The thermostat regulates coolant temperature by either routing coolant back through the engine or to the radiator for further cooling. Electrical the spark plug delivers the electrical spark that ignites the fuel air mixture for combustion. The metal core is insulated from the outer metal casing with porcelain. The spark jumps between these conductive surfaces. The coil pack delivers electrical current to the spark plugs as directed by the ECM or engine control module. The ECM is a computer that directs many core engine functions like spark timing valve open and close timing, air to fuel ratio, etcetera. The alternator works like a power generator, converting the engine's mechanical energy into electricity to charge the battery or run other electrical systems. While the engine is running, the battery provides power to the starter for engine start. Oil. Motor oil is used to lubricate, clean, prevent corrosion, improve sealing, and cool the engine by carrying heat away from moving parts. Rings around the top of the piston head keep oil out of the combustion process while otherwise allowing the cylinder to be lubricated. Oil galleries are channels through the engine block and cylinder head that carry oil to various engine parts. Oil flows through the engine and back to the oil pan for recirculation. Oil rests in the oil pan when not in circulation. The oil pump keeps oil properly pressurized and flowing, and the oil filter keeps oil clean from contaminants. Exhausted, the exhaust manifold collects gases from multiple cylinders into one pipe. Exhaust flows through the catalytic converter, which captures toxic chemicals in engine exhaust and then out through a muffler that reduces exhaust noise. And finally, here's the full functioning engine with all the basic systems we've discussed.